Answering your frequently asked questions to help you better understand machine tools and production processes.

In order to ensure the production quality and functionality of core yarn, we have introduced advanced core yarn equipment, such as core yarn machine, to process both core and outer yarn at the same time, which skillfully combines the strength of core yarn and the softness of outer yarn.

In addition, we are very specialized and experienced in core yarn process and core yarn selection. We have technicians with more than 20 years of experience in the industry controlling the process and material selection to ensure the high quality, strength and softness of the core yarn.

-

Frequently Asked Questions

Frequently Asked Questions -

Customer Service

Customer ServiceFrom installation and training to maintenance and upgrades, your equipment is guaranteed to run efficiently.

-

Supply is stable

Supply is stableOur company has sufficient production capacity and high control over the price, quality and stable supply of raw materials, laying the foundation for continuous production.

-

Brochure

BrochureDownload the product brochure for complete solutions and technical details.

-

AUTOMATED EQUIPMENT AND TECHNOLOGY

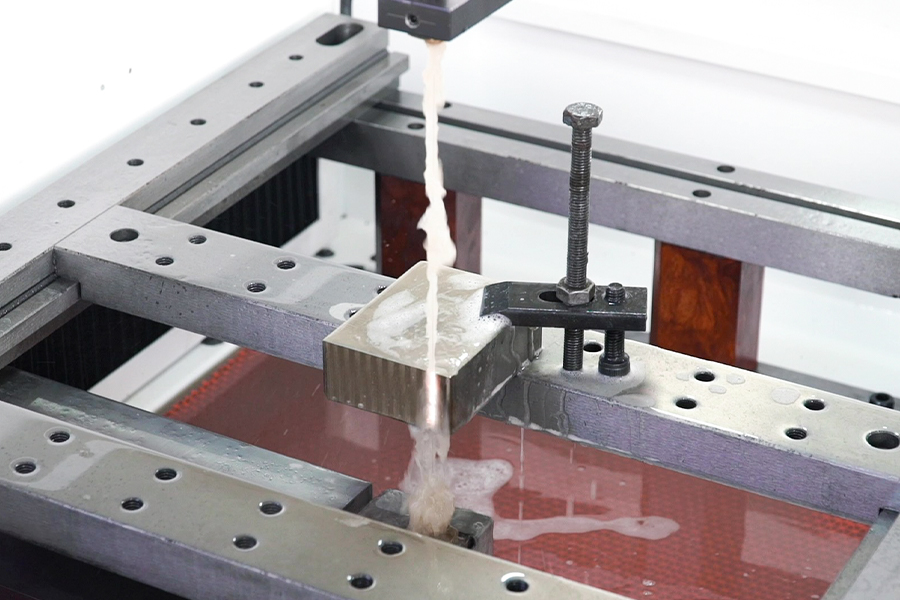

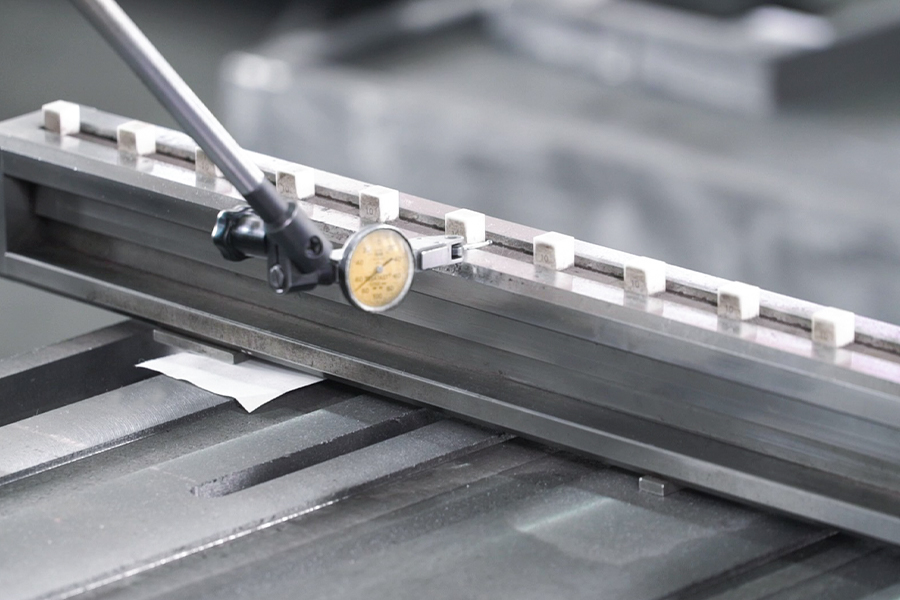

AUTOMATED EQUIPMENT AND TECHNOLOGYNewTopp Precision is equipped with key automation equipment such as multiple CNC machining centers, automatic feeding sawing machines, fully automatic heat treatment equipment, and precision testing instruments.

By automating the layout of key processes, the machining accuracy and production efficiency have been significantly improved, providing strong support for large-scale and high-quality production. -

INTELLIGENT MANUFACTURING SYSTEMSOur company is gradually introducing an ERP production management system, combined with some MES process management, to achieve digital traceability and process control from raw material storage to product delivery.

Through a data-driven intelligent manufacturing system, production transparency, management efficiency, and delivery response speed are effectively improved.- Product supports raw material traceability

- All production lines are equipped with quality inspection

English

English