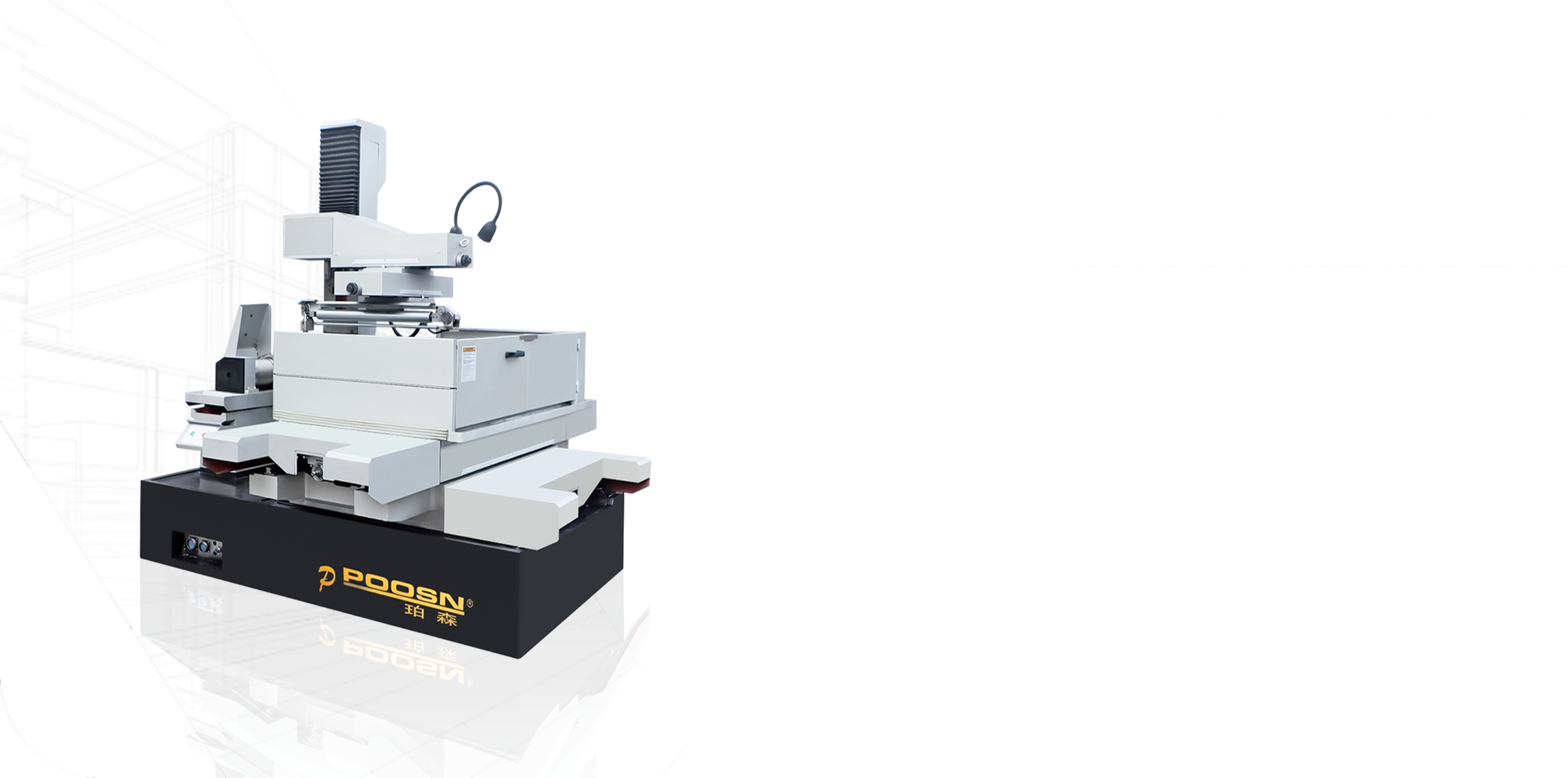

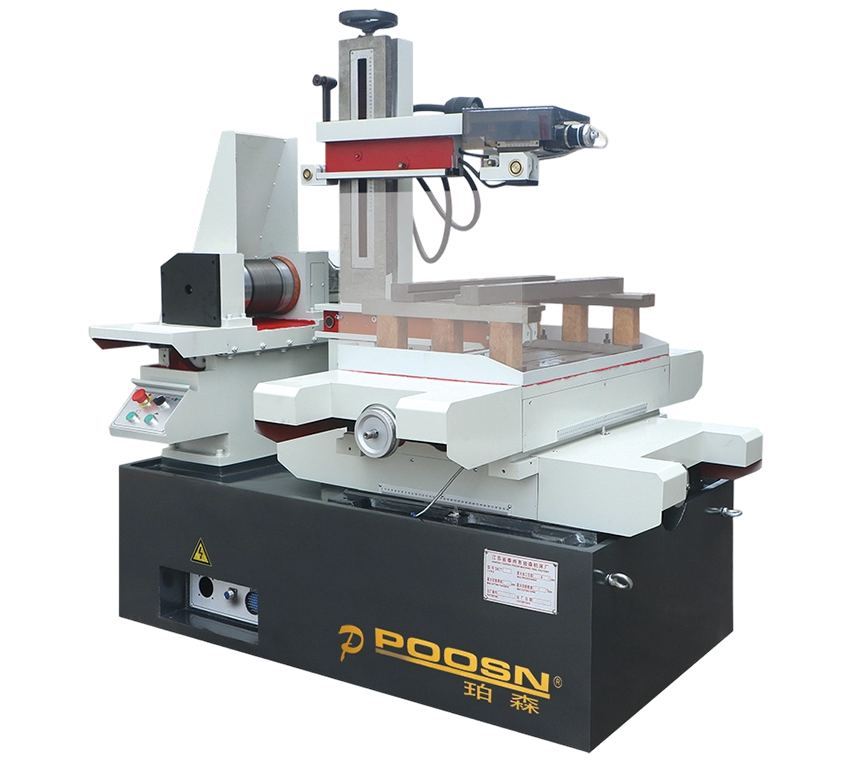

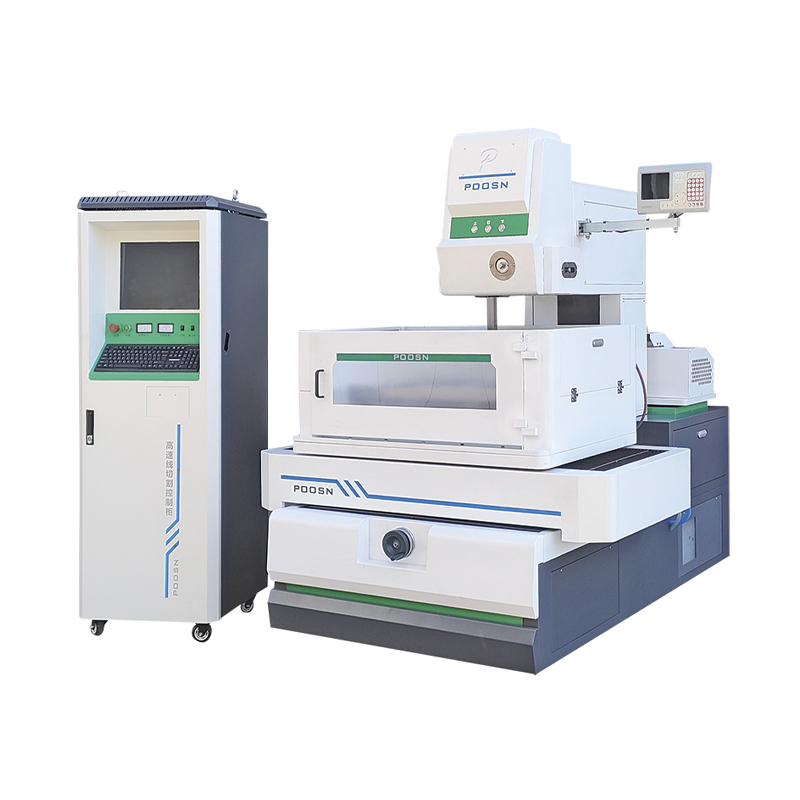

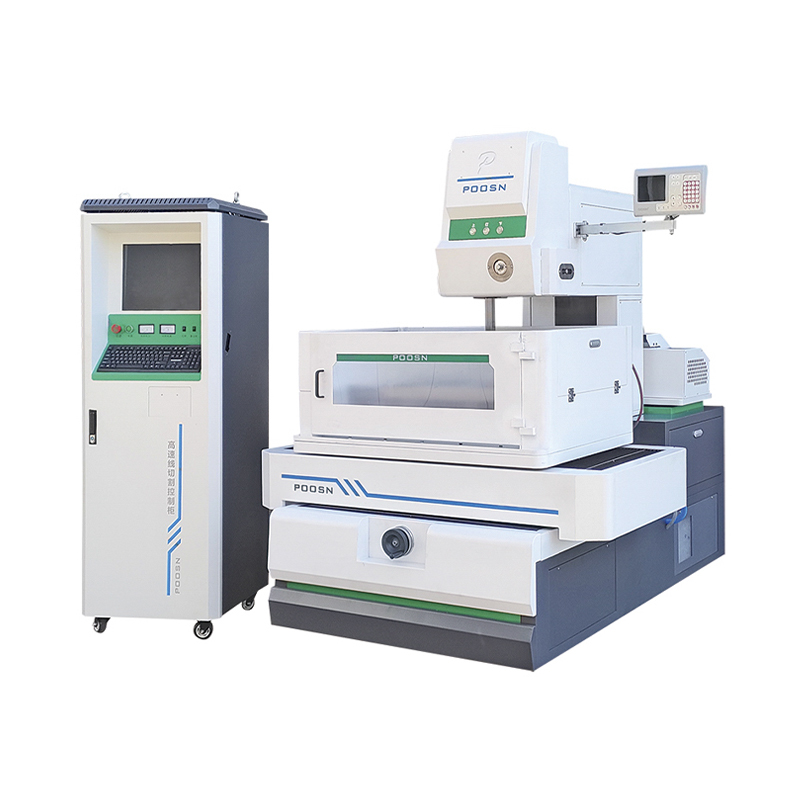

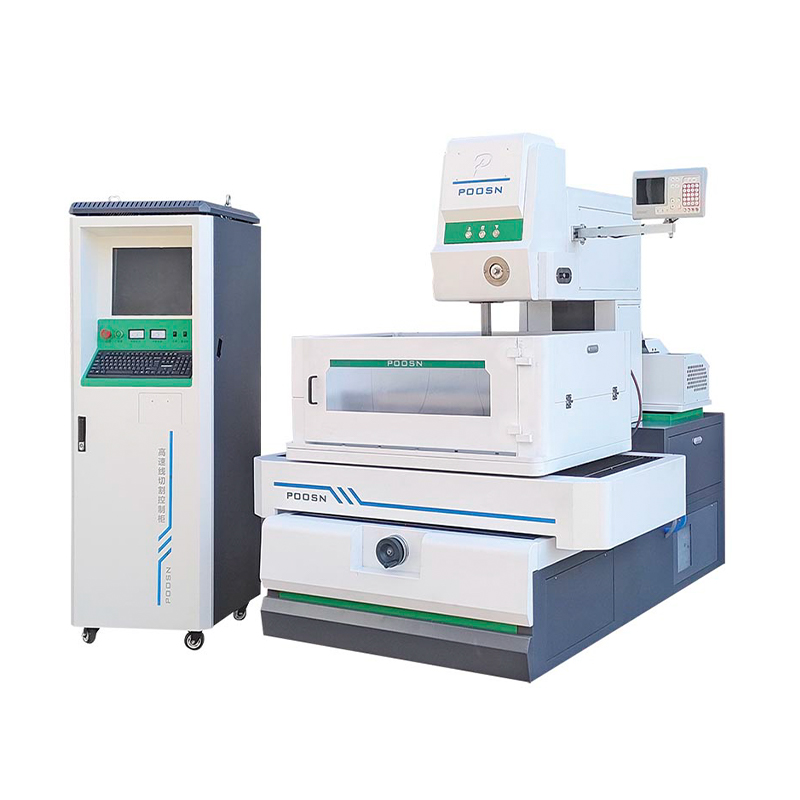

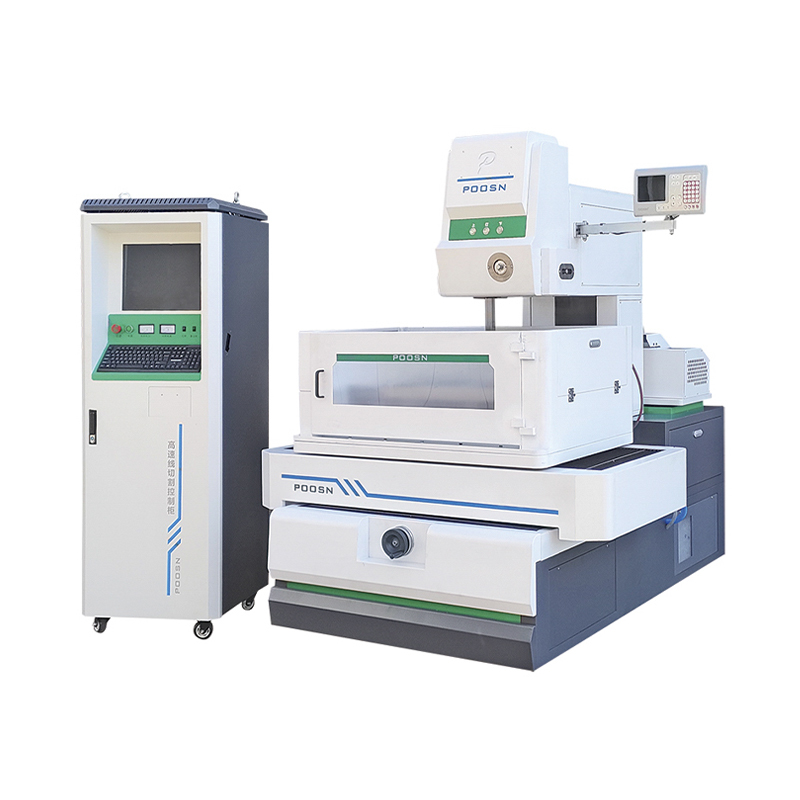

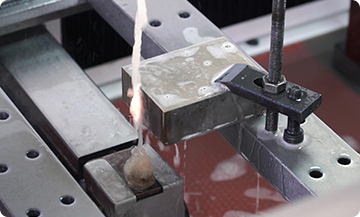

PS60C Medium-speed Wire-cut EDM Machine

PS60C Series Medium-Speed Wire EDM: As the premier high-end model in the PS-C series, the PS60C offers the most robust operational capacity. It is specifically engineered for oversized, high-precision, and heavy-load cutting tasks, making it a staple in demanding industrial sectors.Customization Services & Adaptability·Oversized Customization: Designed for clients with rigorous standards, the PS60C provides the maximum machining area and ultra-high cutting capacity. Customers can customize the worktable dimensions and cutting depth based on the specific size and weight of their workpieces to suit complex processing environments.·Industry-Specific Configuration: Beyond physical dimensions, we offer tailored configurations such as specialized power supplies, unique cutting modes, and automation scripts. These services help maximize productivity and minimize downtime, ensuring stable operation under diverse conditions.·Superior Environmental Adaptability: The PS60C is highly adaptable and capable of maintaining consistent high-precision machining in harsh working environments. It is widely applied in aerospace, heavy-duty mold manufacturing, and large-scale mechanical component production.

English

English