DK45BC High-Medium-speed WEDM

DK45BC Series High-Performance Medium-Speed Wire EDM: Features a larger worktable and higher load capacity, specifically designed for the precision machining of larger workpieces and heavy-duty components. It is ideal for cutting tasks involving complex shapes and large-scale parts.

Technical Innovation & Design

·High-Precision Control System: Utilizes the X8 AUTOCUT control system to ensure high accuracy and a stable cutting process.

·Optimized Wire Feed System: Enhances cutting efficiency and precision, ensuring the smooth completion of production tasks.

·Maximum Cutting Thickness: 450mm, suitable for cutting thick materials and larger-sized parts.

·High Load Capacity: A maximum workload of 400kg, making it suitable for processing heavier workpieces.

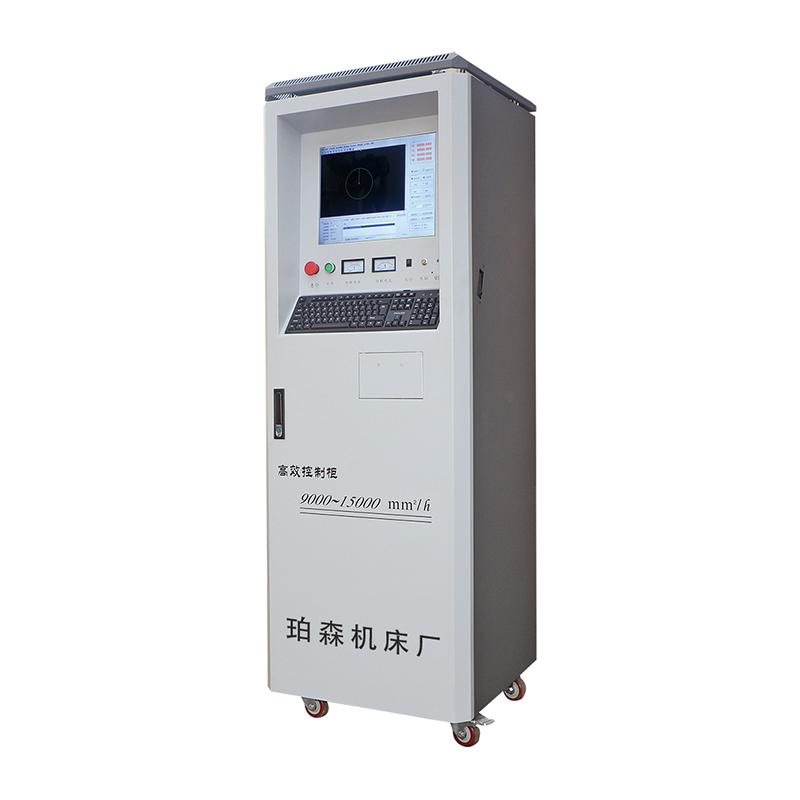

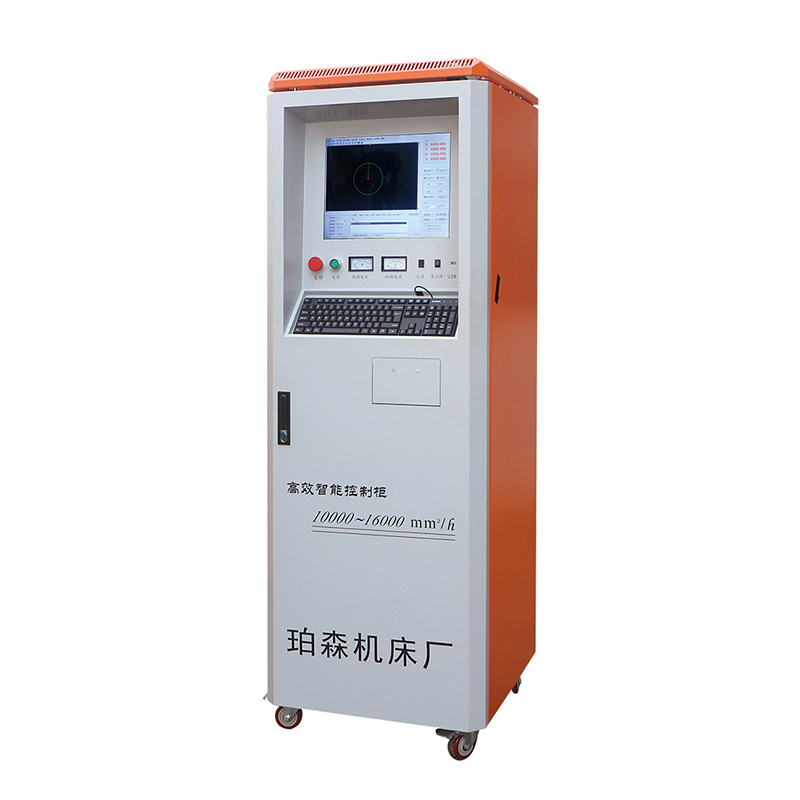

·High Cutting Efficiency: Maximum cutting efficiency ranges from 10,000 to 16,000mm²/h, boosting production output; specific efficiency depends on the selected control cabinet model (three options available).

·Improving Machining Precision: The DK45BC possesses higher machining precision and excellent surface quality, making it particularly suitable for complex parts with high-precision requirements and reducing the need for secondary processing.

·Higher Machining Speed: This machine tool features a fast cutting speed, allowing it to complete more work in a shorter amount of time and significantly improving production efficiency.

·Strong Adaptability: Whether processing soft metals or hard materials, the DK45BC maintains stable cutting performance and adapts to a wide variety of machining needs.

·Mold Manufacturing: Suitable for precision cutting of medium-sized molds, especially for processing molds with thick materials.

·Automotive Parts: Used for processing automotive components, meeting the machining requirements of heavy-duty and large-sized parts.

·Aerospace: Providing high-precision component cutting to ensure part performance and reliability.

English

English