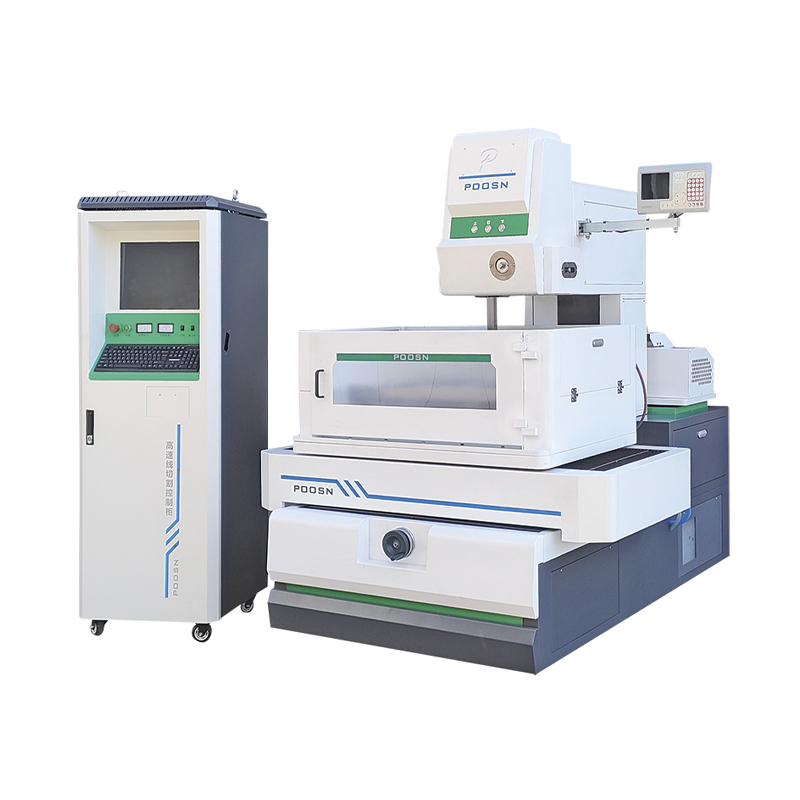

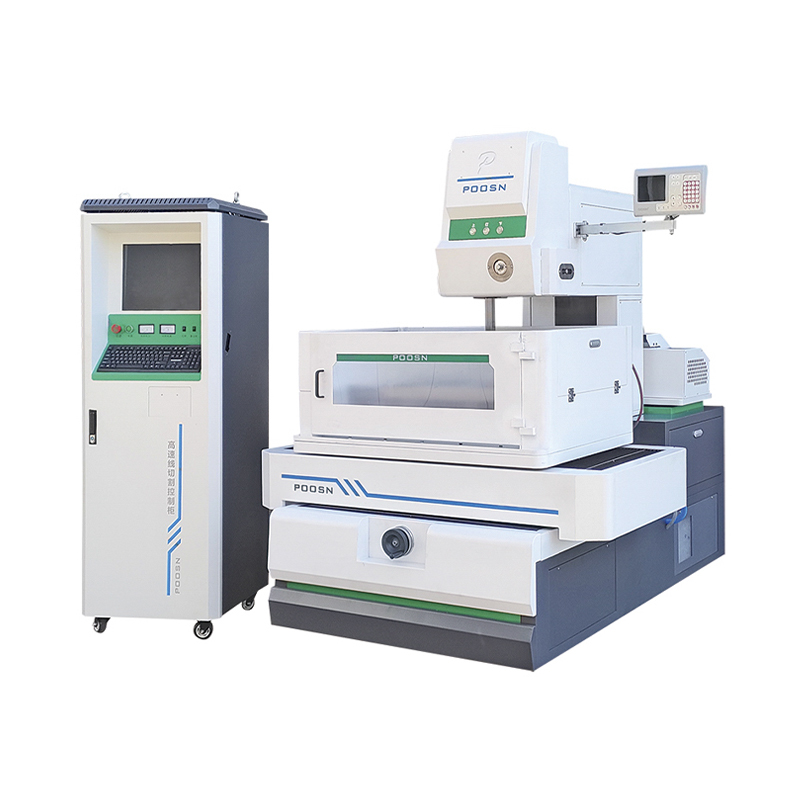

Wire-Cut EDM Machine Operation Process and Fundamental Knowledge

2025-03-03

Wire-Cut EDM Machine Operation Process and Fundamental Knowledge

When selecting a wire cutting machine, customers should prioritize practicality. First, determine the required processing dimensions (length, width, height) for the workpiece. Based on these specific measurements, choose the appropriate wire cutting machine model. Operational issues are inevitable with wire cutting machines. Only by correctly identifying these problems and having them repaired by professional technicians can the machine maintain consistent performance. If customers encounter unfamiliar issues, they should contact the manufacturer for solutions. For non-professional high-speed wire cutting operators who are fascinated by the process, high-speed wire cutting holds an air of mystery. Understanding how to perform high-speed wire cutting has become knowledge many aspire to acquire. After reading this article, many readers will gain insight into these procedures.

Step 1: Identify the Cutting Object

When receiving a workpiece for processing, the operator must clearly identify the areas requiring wire cutting, along with the required dimensions and surface finish specifications. After clarifying these details, consider the cutting approach, how to position the workpiece on the machine, and how to determine the machining process. Although this first step seems complex, it can be broken down into several sub-steps. In practice, however, these are relatively straightforward. Once the primary point is established, the subsequent steps can be completed efficiently.

Step 2: Drawing and Programming

This step demands the highest technical skill and knowledge. First, open the control panel of the high-speed wire-cutting EDM machine. Click “Return” with the mouse to enter drawing mode and proceed according to the shape determined in the previous step. Drawing requires programming. After programming, follow this sequence: Press “Execute 1” → Enter compensation gap value of 0.1mm → Post-process → Save G-code machining file → Save file name: 81 → Save to HF directory → Return to control panel → Read disk → 81 → Confirm.

Step 3: Install the Electrode Wire

First load the electrode wire, then thread it. Rotate the wire reel to its rightmost travel limit, tighten the limit switch, and secure one end of the electrode wire to the reel with a screw. Place the wire spool over the threading rod, tighten the nut, and ensure the wire won't fall off the spool. Use the crank handle to rotate the reel. When the reel approaches its opposite travel limit, cut the electrode wire. After threading the electrode wire, crank the spool clockwise over ten turns, then tighten the left-end limit switch.

Step 4: Mounting the Workpiece

Ensure the workpiece fits within the machine's working envelope. Numerous mounting details require attention, which I won't elaborate on here.

Step 5: Process the Workpiece

Operate the control system to initiate machining, as modern wire-cutting machines are now automated.

Step 6: Inspect Finished Product Quality

Measure dimensions with a gauge and verify surface smoothness meets specifications.

The above outlines the wire-cutting process for high-speed wire-cutting machines. In practice, the programming for these machines is quite complex and requires individuals with a solid knowledge background to fully master.

English

English