How to Select the Configuration for a Wire-Cut EDM Machine

2025-03-03

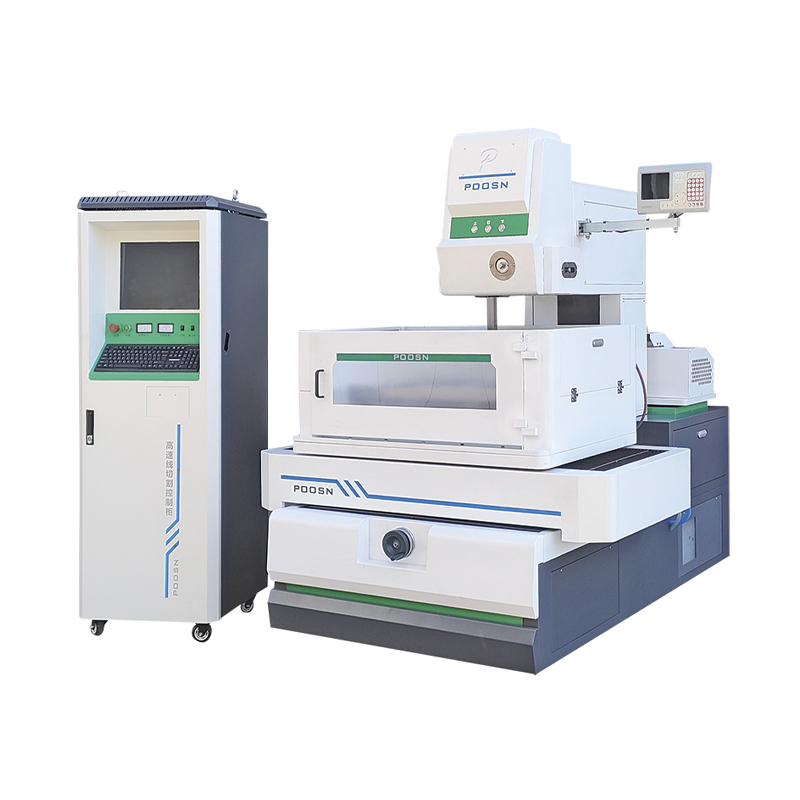

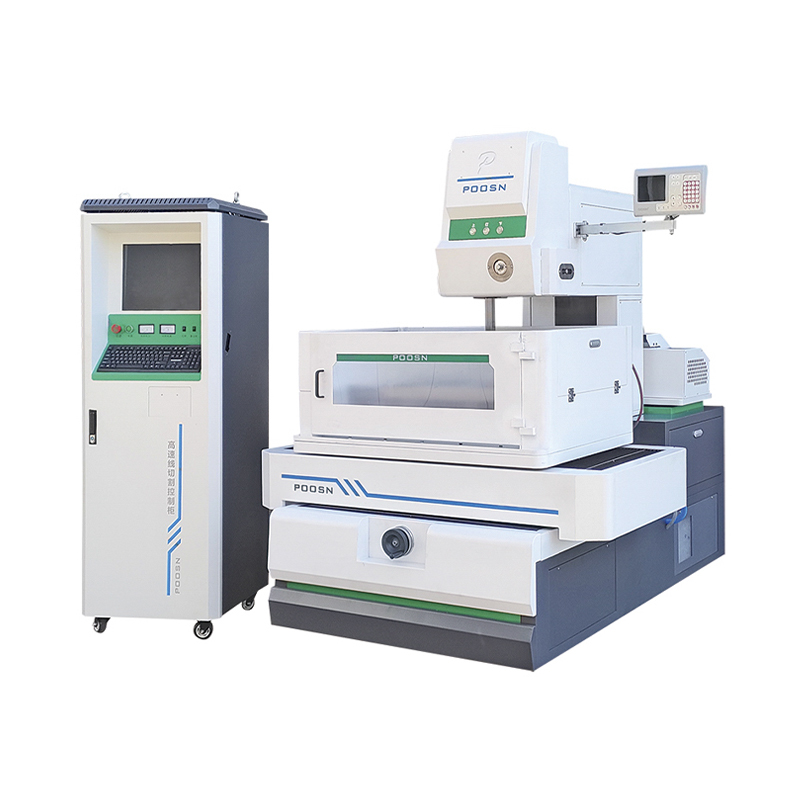

Since the year 2000, manufacturers have invested significant resources in enhancing the processing speed and precision of medium-speed wire-cutting EDM machines. Despite considerable effort devoted to meticulously developing these machines, the results have consistently fallen short of expectations. In recent years, medium-speed wire-cutting EDM machines have entered a mature phase, achieving new heights in machining precision, speed, and surface finish. Gradually gaining market recognition, their demand has risen year after year. Yet, for general users, selecting and configuring these machines to achieve optimal results remains a challenge, as the selection process is highly nuanced. Previously, standard high-speed wire-cutting machines equipped with medium-speed control cabinets could achieve repeatable machining and tool repair functions, effectively functioning as medium-speed machines. However, modern genuine medium-speed wire-cutting machines offer far more capabilities. Visually, medium-speed machines differ significantly from high-speed ones. Modern medium-speed machines feature an aesthetically pleasing, streamlined design with automatic wire tensioning. Their sealed construction prevents emulsion oil leakage. Optional configurations include linear guides, servo motors for drive systems, computer control cabinets with automatic programming capabilities, and data storage functionality.

English

English