TECHNICAL PARAMETERS

◆ Worktable standard equipped with imported linear guides;

◆ Adaptive constant-tension wire tightening mechanism (Optional);

◆ X8 system(Standard),CAXA CAM2019 or TCAM (Optional);

◆ Non-destructive high-precision center hole positioning;

◆ Worktable standard equipped with grating scale for real-time full-stroke position monitoring;

◆ Full series standard with high-speed power supply or nanosecond power supply;

◆ Taper cutting full series standard with linear guides and ball screws;

◆ Z-axis full series standard with one click depth setting via linear guides.

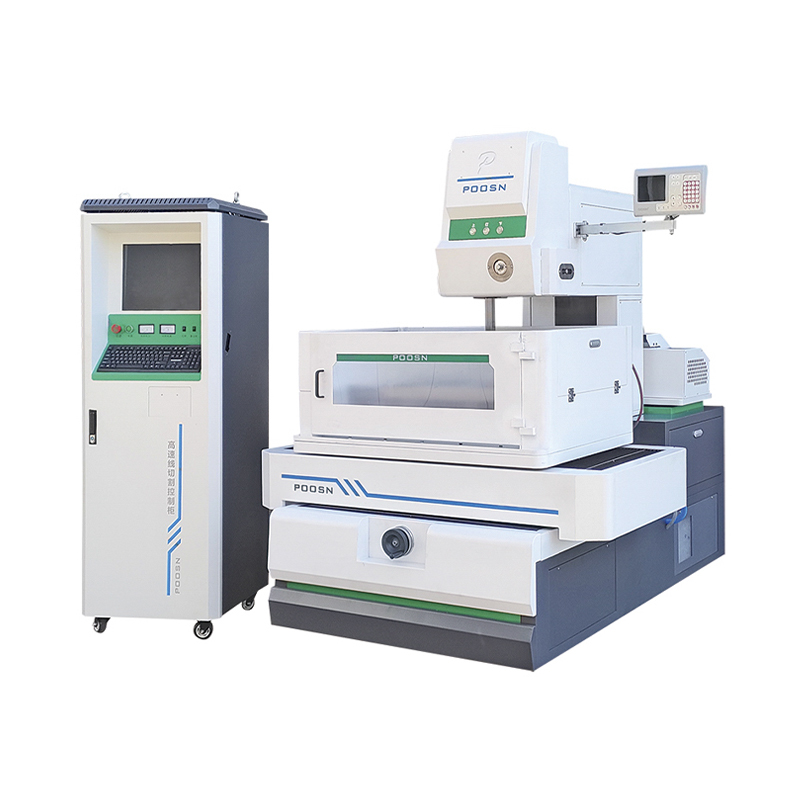

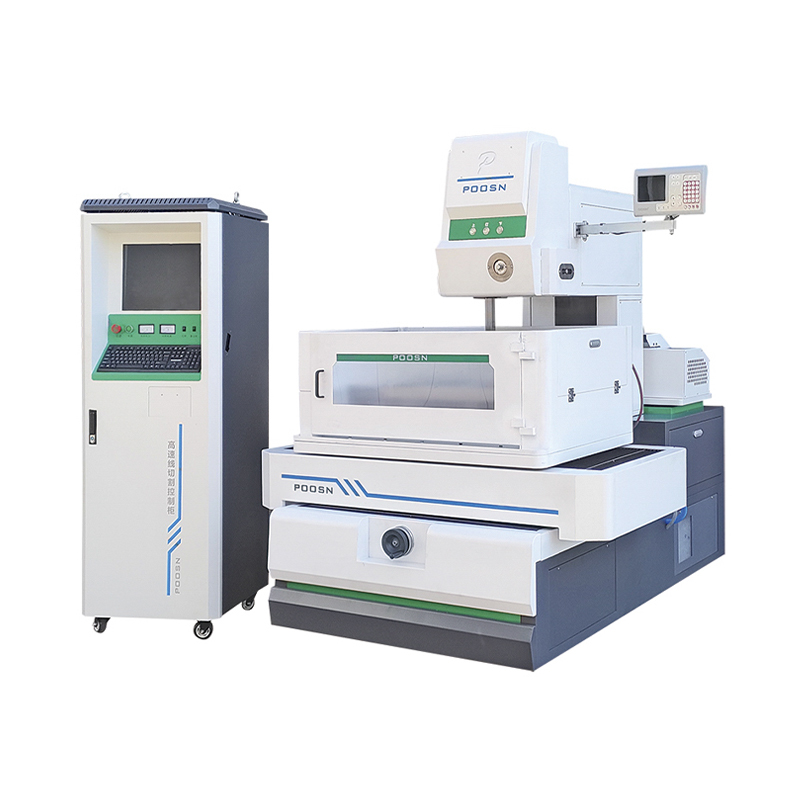

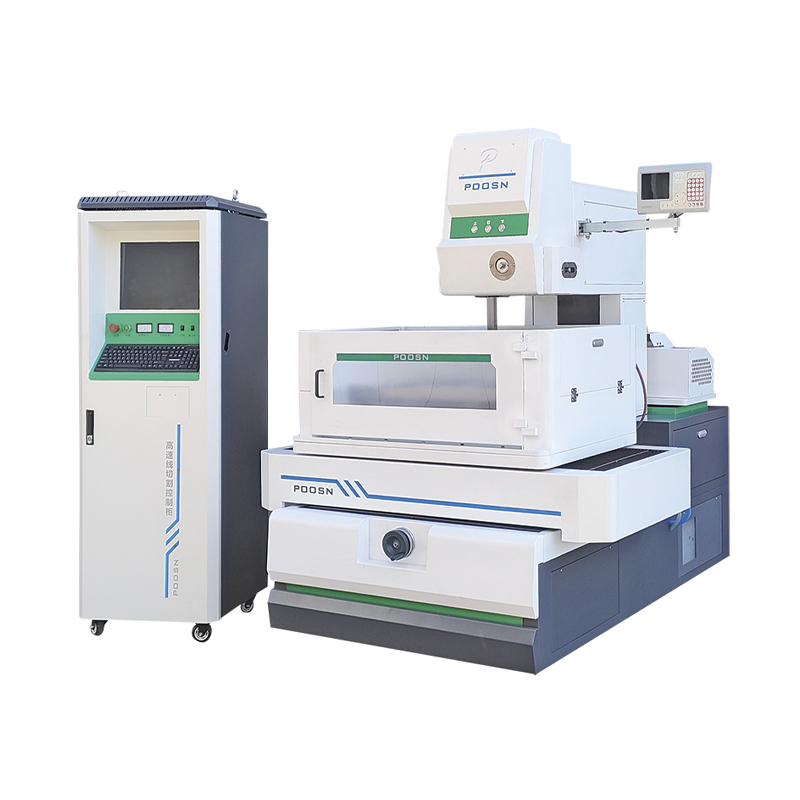

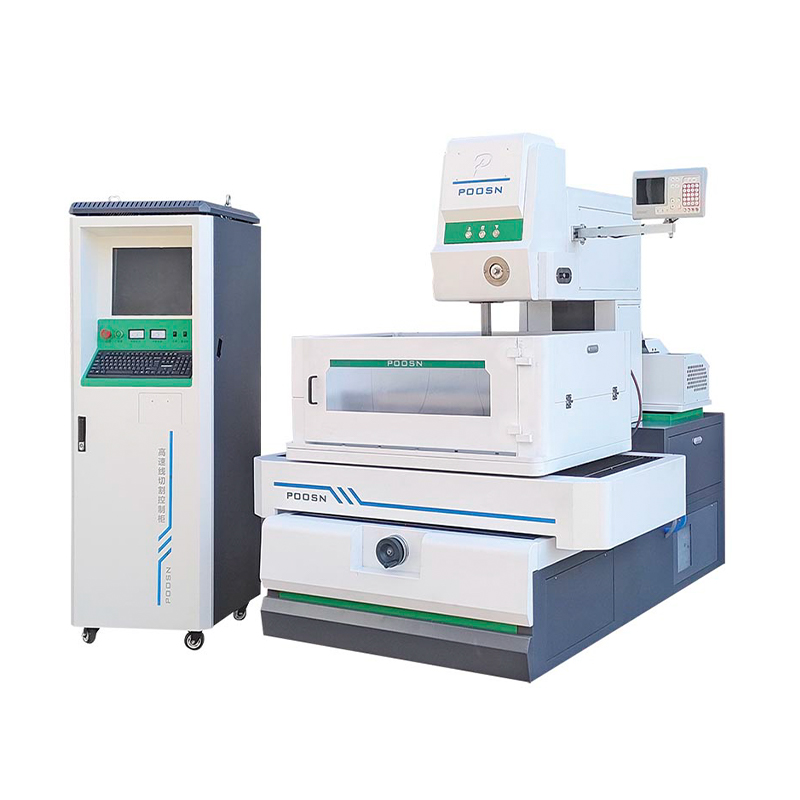

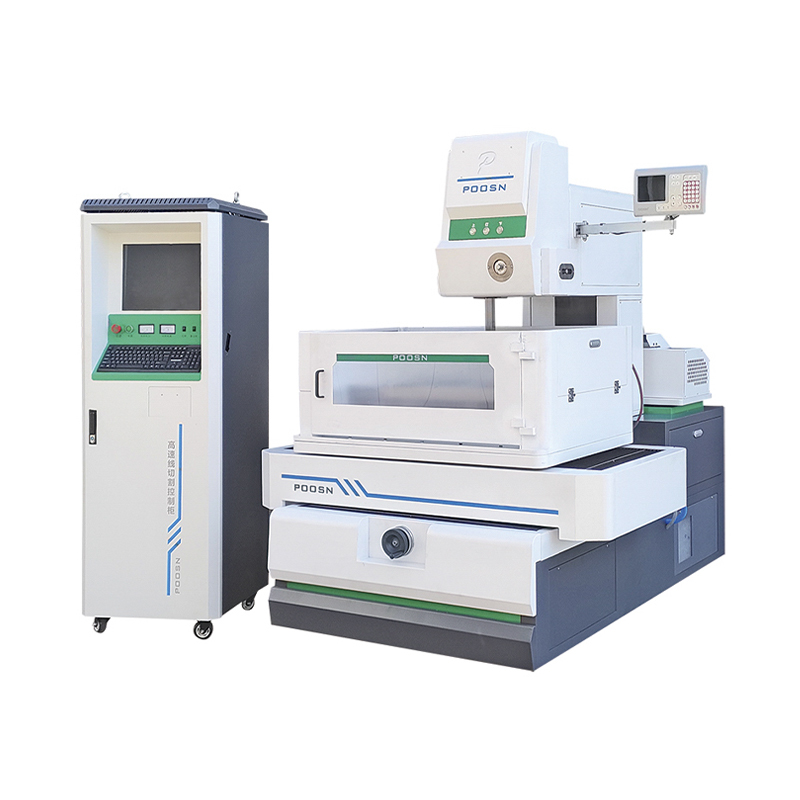

Medium-speed Wire-cut EDM Machine

·Powerful Core

Equipped with an advanced patented eco-friendly pulsepower supply, it effortlessly achieves low electrodewear, high-speed processing, low surface roughness, and high energy efficiency with minimal environmental impact. Imported frequency converters enable smooth directional switching, extending the mechanical lifespan of the wire drive system. The intelligent integration of these technologies ensures consistent surface roughness. The novel patented constant-tension mechanism addresses the sluggish response of simple weight-based tensioning systems to wire tension fluctuations, minimizing variations in electrode wire tension. Even during taper cutting, dynamic constant tension is maintained.

·Intelligent Control System

A professional industrial control computer ensures long-term stable and reliable performance. As the first domestic manufacturer to adopt imported AC servo systems, it achieves faster processing speeds and higher precision in multiple-cut operations. Equipped with interfaces such as LAN and USB for seamless data exchange. The intelligent programming system simplifies the generation of G-code programs.

·Robust Skeleton

High-strength resin sand castings and a thoughtfully designed machine structure ensure sufficient rigidity and stability. Advanced aging treatment technology prolongs the consistency of mechanical precision. The integration of AC servo systems with high-precision linear guides, ball screws, and pitch error compensation enables the machine to mirror the precision of low-speed wire EDM. The innovative anti-splash design effectively minimizes working fluid splatter, maintaining a clean processing environment.

One-touch motor automatic threading

It is convenient and efficient, reduces manual labor intensity, and enhances safety.

Waterproof gem guide wheel

The φ40 single-sided gemstone guide wheel is designed for easy threading, long life, and high precision.

Automatic double-sided tightening mechanism

Automatic double-sided tightening prevents molybdenum wire vibration and single-sided loosening.

High-quality HT250 castgs with a T-shaped bed

This is superior to conventional strip-shaped beds. Its characteristic is that the worktable can only move within the confines of the base, preventing deformation and ensuring long-termstability of the machine tool.

Large cutting taper

U and V axis P-grade linear guides. Optional: U and V combination, servo motor, linear guide, ballscrew.

Liftable Gem Wire Guide

Advantage 1: The wire guide allows for maximum proximity to the workpiece surface during machining, reducing wirevibration and improving machining accuracy and surface finish.

Advantage 2: The cutting height range can be adjusted without rethreading the wire, facilitating manual operation and improving work efficiency.

Driven by the Panasonic servo motor

Taiwan brand High-precision linear guides, ball screws and C-type wire frames.

Imported bearings

All motion mechanisms utilize Japanese EZO bearings.

Machine Tool Performance Characteristics

1. Automatic tracking water spraying during the cutting process;

2. Automatic spring wire tension;

3. Convenient replacement of the main guide wheel;

4. Taper device equipped with linear guides and ball screw pairs;

5. CNC stroke for U and V axes:

400×400mm(±30°)

590×590mm(±45°)

Linear guide rail lifting is optional.

| Model |

PS35C |

PS45C |

PS50C |

PS60C |

| CNC Worktable |

| Worktable Size |

550×826mm |

650×926mm |

740×1060mm |

840×1160mm |

| XY Travel Size |

350×500mm |

450×600mm |

500×700mm |

600×800mm |

| Processing Slot Size |

545×910mm |

645×1010mm |

740×1150mm |

840×1250mm |

| Max.Cutting Thickness |

280mm |

280mm |

350mm |

430mm |

| Max.Worktable Load |

300kg |

400kg |

600kg |

800kg |

| Tapering Device |

| UV Travel Size |

60×60mm |

| Max.Cutting Taper |

±6°/80mm |

| Wire Feed System |

| Max.Travel size of wire drum |

180mm |

| Electrode Wire Diameter |

Φ0.18mm(With wire guider) |

| Wire Feed Speed |

1~11m/s Frequency control |

| Max.Wire Storage Length |

≈320m |

| High-Pressure Water Tank |

| Fluid Tank Capacity |

80L |

| Fluid Filtration Method |

Paper core filter |

| Test Piece Processing Specifications |

| Processing Accuracy |

0.01mm |

| Max.Cutting Efficiency |

10000~16000mm²/h |

| Optimal Surface Roughness |

Ra≤1.2μm(Multi-cutting) |

| Drive Control |

| CNC Worktable |

Standard: XY stepper drives Optional: XYAC servo drives |

| CNC Taper Device |

UV3P stepper drives |

| Z-Axis Lift |

Electric motor AC 220V |

| Number of NC Controlled Axes |

X、Y、U、V Four-axis linkage |

| Electrical and Programming System |

| Programming System |

X8/AUTOCUT control system |

| Control Cabinet Model |

ZHZ-09G |

| Max.Processing Current |

6A |

| Electrical Capacity |

2.5kVA |

| Power Supply |

3N 380V±10 |

| Machine Weight |

1600kg |

2000kg |

2200kg |

2700kg |

| Machine Dimensions |

1835×1530×2010mm |

2010×1655×2010mm |

2300×1865×2200mm |

2500×2065×2300mm |

| ★Customizable options available for PS60C and above machines. |

TECHNICAL PARAMETERS

Q1: Compared to the PS35C, in what aspects has the PS45C been improved?

A1: Compared to the PS35C, the PS45C features an X-axis stroke of 450mm and a Y-axis stroke of 650mm, enabling it to handle larger workpieces. It has a stronger load capacity, making it suitable for the precision machining of medium-to-large components, and offers higher cutting efficiency suitable for mass production.

Q2: What is the maximum cutting thickness of the PS45C?

A2: The maximum cutting thickness of the PS45C is 280mm, which allows it to handle thicker materials and complex parts that require high precision.

Q3: Can the PS45C meet higher production efficiency demands?

A3: Yes, the maximum cutting efficiency of the PS45C can reach 10,000 to 16,000 mm²/h, making it particularly suitable for cutting larger-sized and higher-load components. The specific efficiency depends on the model of the control cabinet selected; we offer 3 types of control cabinets.

Q4: Which industries are the PS45C's processing capabilities suitable for?

A4: The PS45C is widely used in industries such as mold manufacturing, precision machinery processing, and aerospace. It is especially suitable for components with high requirements for processing accuracy and larger workpiece dimensions, providing stable, high-precision cutting.

Q5: Is the PS45C suitable for automated production environments?

A5: Yes, the PS45C supports a certain degree of automation and can be integrated with other equipment and production lines to improve production efficiency and reduce manual intervention, making it very suitable for automated production environments.

Model Selection Advice:

·PS35C: Suitable for small parts and small-to-medium batch production, especially in scenarios requiring high cutting precision and high processing efficiency.

·PS45C: Suitable for processing medium-sized parts, providing a larger workbench and higher load capacity; applicable for larger molds and precision components.

·PS50C: Suitable for processing large-sized and heavy parts, especially for production tasks with high requirements for precision and load capacity.

·PS60: Specially designed for extra-large workpieces and high-load components; suitable for heavy-duty molds and high-demand industries such as aerospace.

TECHNICAL PARAMETERS

We provide rapid response and professional technical support to ensure the operational stability of your equipment. Our commitment is to guarantee the long-term effectiveness and reliability of every machine we deliver.

English

English